Try eMaint for free

Eliminate unplanned downtime

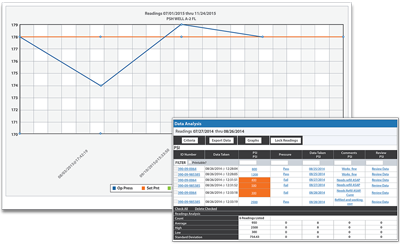

Be proactive in avoiding equipment downtime by scheduling maintenance as needed based on analysis of asset condition data.

Reduce work order backlog

Improve efficiency by auto-triggering work orders when a calendar date or meter point is met, and viewing open work by type, technician, craft, etc.

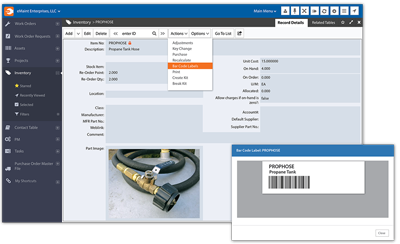

Improve spare parts accountability

Save time and budget by associating spare parts with assets and PMs, automatically reordering parts, and implementing barcoding.

The two brands you trust, Fluke and eMaint, have joined forces to usher in a new era of maintenance connectivity for customers in the industrial world. With a seamless integration of hardware and software solutions, maintenance teams can continuously monitor and trend equipment data and move toward a predictive maintenance strategy.

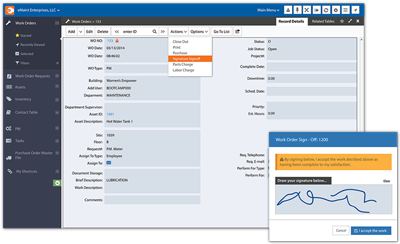

Work orders and requests

Generate work orders and submit work requests via a login, email or form

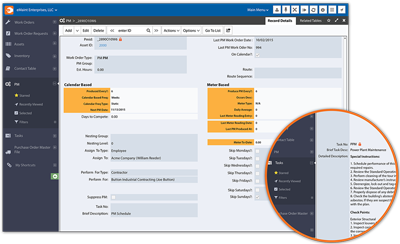

PM tasks and schedules

Generate PM tasks, develop PM schedules on time or usage, and track inspections

Parts and inventory

Manage and track spare parts, suppliers and purchase orders

Get the maintenance management software you need from the brand you trust

Predictive maintenance

Define boundaries for equipment operation, import readings and graph results

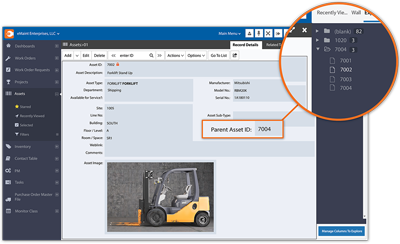

Asset management

Establish asset hierarchies, track maintenance history, and prioritize work

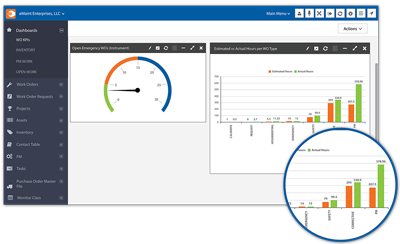

Reports and dashboards

Analyze trends and make data-driven decisions with robust reporting tools

50,000+ users worldwide rely on eMaint to predict failures, eliminate downtime, and improve reliability

"We are able to support our customers, deliver on objectives and ultimately drive growth by partnering with eMaint."

Chris Hooge

Fleet Manager at Boasso America

"eMaint provides us with visibility into processes and the ability to make more informed, data-driven decisions."

Jeffrey Martin

Quality Systems Specialist at Schneider Electric

Ready to improve the way you manage maintenance?